Explanation for robotized assembly task description (E1)

The activity chosen for potential robotization is the installation and fastening of screws in the assembly process.

Assembly process

Currently there are 6 people working on an assembly line for products which require fastening with screws. Manual screwdrivers with controllable torque are currently used. The entire process is being completed manually by operators. The primary issues with operators are related to human-issues such as lost time due to illness and breaks, a high cost; and with the production quality as people tend to make mistakes as well as quality control is lower due to lack of factual quality control.

Currently the process consists of the five following steps on conveyor in the assembly workstation:

1. Picking the housing from shelf and placing to the work area

2. Picking PCB from shelf and placing to the work area

3. Placing the PCB on housing

4. Picking up screws

5. Screwing the PCB onto the housing

After finishing these steps the assembly is being moved on the conveyor to the testing station.

After testing the finished product is sent on the conveyor to the packing station.

Nomenclature

Manufacturing is a mix of serial production and made-to-order production. As of today, the orders for the next month are as follows: TV-remotes, walkie-talkies and safety boxes. TV-remotes and walkie-talkies have orders for more than 20 000 products in total, safety boxes have an order of total 4000.

Amount

The mass production products are produced in high volumes - 24 000 pieces per month. The number of custom made products for clients is small - only one order with less than 5000 units per order.

Business model

As a sub-contractor the company is working based on the needs of the client. There are many clients who all want different products and therefore, the quantities and quality specifications vary greatly. There are clients who order for a longer period of time and also one-time orders. The manufacturing of the longer period orders can be called mass production where the products are standardized. One-time orders, however, are made-to-order and there are lots of different products produced in low volumes.

Integration

As the production is working on a conveyor line method, the integration of the robot is not needed with the rest of the machines except with the line itself. As the line is equipped already with sensors and stoppers to ensure no product is missed during the manufacturing then there would not be any problem about understanding whether the product is on the line or not. The integration with the robot could be easily integrated with the line if needed as the line is prepared to be connected with other systems.

Furthermore, there is an information sharing process set up to collect and store data received from production lines. The process has been set up with keeping in mind possible future additions to the system which allows to easily add the robot into the same data collection system with the rest of processes.

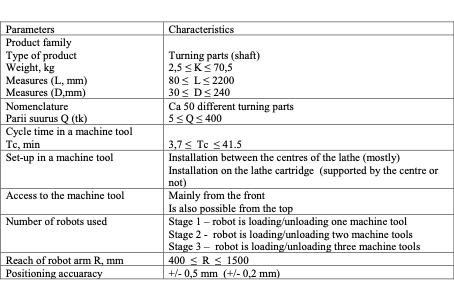

Explanation for robot selection of a machine tending operation (E2)

Production task. The robot-cell is planned for manufacturing turning parts with measures D= 20 -45 mm, with length L = 30 – 200 mm. The batch sizes are from 20 to 1200 pieces. Repeatability of batches is existing. The nomenclature is approximately (60 – 100 different workpieces).

One possible solution

The industrial task is not very complicated. The company has previous experiences with the producer of robots. There are also other advantages for using this robot for a current manufacturing task.

HC-10 Robot

| Controlled Axes | 6 |

| Payload | 10 kg |

| Max Working Range | 1200 mm |

| Repeatability | 0.1 mm |

| Weight | 47 kg |

| Power Supply | 1 KVA |

| S Axis | 130 º/sec |

| L Axis | 130 º/sec |

| U Axis | 180 º/sec |

| R Axis | 180 º/sec |

| B Axis | 250 º/sec |

| T Axis | 250 º/sec |

Industrial robot for machine tending

Explanation for robot justification (E3)

a. Payload: The Aluminium housing has a weight of 12 kg. So the robot should be capable of carrying weight up to 15 kg.

b. Size: Size should not be very big. It should be easily fit inside the workplace and should have some area for technician movement.

c. Working range: Working range should be enough so that the robot can easily reach to input/output buffer and trim press machine.

d. Movement: the robot should have 6 degree of freedom (Dof). Both position and orientation should be controlled. Picking and placing of parts will be easily achieved using 6 Dof.

e. Energy: The Robot should consume less energy. The same work can be done using different kinds of robot. But the Robot consuming less power should be used.

f. Quality: Applications should be performed with precision and high repeatability every time. It ensures the product is manufactured with the same specifications and process every time. Repairs are few and far between.

g. Customer satisfaction: If the Quality of the product is good customer will be satisfy, which means returning customers and more business.

h. Safety: Robot should increase workplace safety. Robot should stop working if anyone inside the working area of robot. Light screens or barriers should also be available to keep the operator out of arms way.

i. Cost: The cost of the Robot is also an important factor.

Explanation for decision making in robot selection (E4)

Industrial task description

Industrial robot comparison

| Industrial robot technical parameters | Fanuc M-710iC/20L | ABB IRB 6650S – 90/3.90 | Yaskawa MH50-20II |

| Load capacity, kg | 20 | 90 | 20

|

| Weight, kg | 540 | 2275 | 495

|

| Reach, mm | 3110 | 3900 | 3106

|

| Average power consumption, kw

|

2,5 | 2,4 | 3,6 |

| Maximum speed o/s

J1 |

175 | 100 | 180

|

| Maximum speed o/s

J2 |

175 | 90 | 178

|

| Maximum speed o/s

J3 |

180 | 90 | 178

|

| Maximum speed o/s

J4 |

350 | 150 | 400

|

| Maximum speed o/s

J5 |

360 | 120 | 400

|

| Maximum speed o/s

J6 |

60 | 235 | 600

|

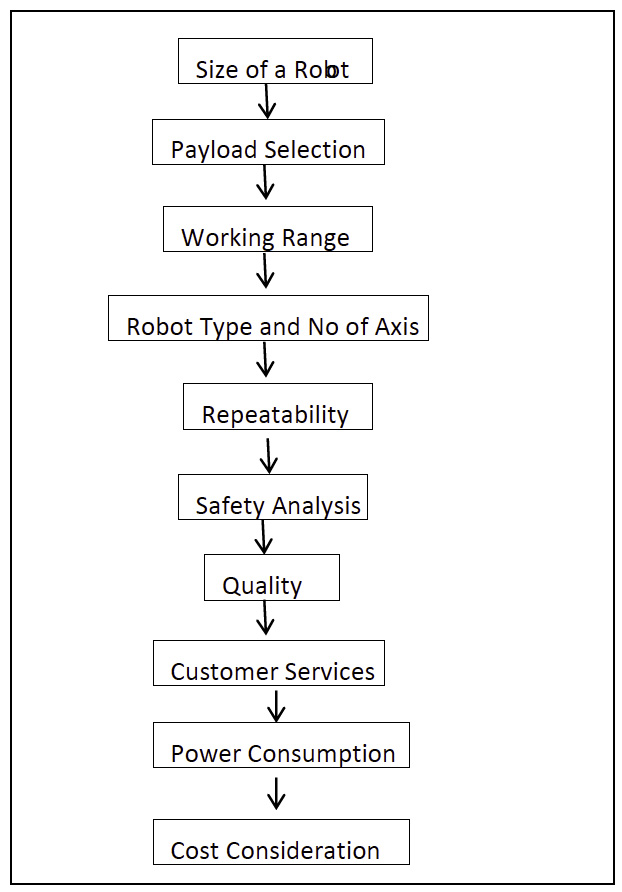

Explanation for the Industrial robot selection sequence (E4)

In the following the industrial robot selection procedure is given.

Industrial robot selection procedure

As mentioned earlier the working task parameters are compared with the industrial robot technical capabilities. One IR justification description is given in the following

Explanation for the robotization task complete design (E5) - Packing and palletizing robotization

Problem description

The problems involved in the automated packing and nesting of irregular shapes are not only of theoretical importance, but have considerable industrial interest. The ability to manipulate objects under visual control is one of the key tasks in the successful implementation of robotic, automated assembly and adaptive material handling systems. Such systems must be capable of dealing with a wide range of variable products and of operating in industrial environments that are not overly constrained. These systems will need to include the ability to manipulate arbitrary shapes in a flexible manner. Therefore, to automate this part of the manufacturing process we need to develop automated material handling systems that combine machine vision techniques and flexible packing strategies [5.1].

There are following given some of the main principles of packing [5.2]:

-

- Sequential assignment heuristics, packing of patterns based on a set of assignment rules. The majority of heuristic approaches consist of determining what order and orientation the pieces should be packed in.

- Single-pattern generating procedures such as dynamic programming based algorithms which try and reuse a single 'optimal' packing configuration. For example, in the two-dimensional rectangular packing problem the solution is built up by considering partial solutions within smaller containing rectangles.

- Multi-pattern generating procedures such as linear programming1 based approaches which consider the interaction between patterns. This approach requires the solutions to be rounded and are, therefore, also heuristic in nature. The packing task can be formulated as a binary integer problem in which a single variable represents each possible piece position. For example a rectangle could be represented by a top left coordinate. A major concern with this approach is the production of a physical design from the values of the variables in the integer programming solution.

A practical review of two and three-dimensional packing issues and solution methods can be found in paper [5.2]. The majority of the applications outlined in this review are based on two-dimensional packing techniques. Many of the three-dimensional problems are tackled by applying two-dimensional techniques on a layer by layer basis. Most published work in the area of three-dimensional packing is limited due to its complexity, and the applications that are discussed tend to be concerned with the loading of shipping containers. The paper also summarises some of the practical requirements in pallet loading, these include:

• The stability of the loading stack.

• The load bearing ability of the items in the stack.

• Ease of stacking.

• Air circulation requirements of certain products in a stack.

Automated packing/nesting and automated assembly are closely related tasks. In the majority of assembly systems, the parts only fit together in certain ways, dependant on their shapes, and they can only be moved into their fitting positions in ways that are also dependent on their shape. This shape-dependent part-fitting is a key feature in any assembly application [5.3]. A primary source of difficulty in automated assembly is the uncertainty in the relative position of the parts being assembled. This uncertainty can be significantly reduced by the use of vision and tactile sensors.

In the paper [5.4,5.5] the authors have given a good overview of the application of part nesting in intelligent robotic packaging and processing systems, as well as outlining robotic game playing systems and actual solutions to a number of industrial problems. A system for the automated palletizing of randomly arriving parcels, has been developed by the authors. In the development of such industrial systems, the authors have taken account of the some of the various systems issues involved in such a design. In such a system, heuristics are necessary to deal with the interlocking and intermeshing of the boxes on the pallets as well as dealing with the toxicity and crushability of the boxes contents. Other areas of related research include the work [5.5.5.6], in which they discuss the development and implementation of a knowledge based system for three-dimensional automated assembly tasks, under robotic control.

When faced with a specific application requirement, it is always well worthwhile analysing the problem from a systems engineering perspective. By adopting a systems approach, the maximum use is made of problem-specific "contextual" information, derived, for example, from the nature of the product being handled, the process used to manufacture it and the special features of the manufacturing environment. By doing so, the complexity of the application is hopefully reduced. For example, it may be found that, by mechanically restricting the orientation and the order of arrival of objects considered by the packing system, the problem can be simplified. In fact, by taking heed of such constraints, in a practical packing application, the procedure might well reduce to a standard, well-tried technique. It is our belief that in packing, as happens so often elsewhere, systems considerations are always worth investigating. Table 5.1 summarizes some of the practical considerations found in the industrial implementation of automated packing systems, that if considered within a systems engineering framework, can often reduce the complexity of a given application.

Table 5.1 Packing conditions

-

-

-

- Packing density.

- Object fragility.

- Object rigidity.

- Surface finish (Objects with a smooth finish will be easier to slide/push).

- Object clampabilty.

- Ease of stacking.

- Packing stability.

- Load bearing ability and the effect of dynamic forces.

- Interaction between the packaging material and its contents.

- Electromagnetic radiation.

- Possibility of contamination of adjacent goods.

- Importance/value of the article.

- Protection from pilferaging.

- Need to provide ullage or vacuity.

- Probable number and nature of loadings and unloadings.

- Minimization of robot arm movement during loading and unloading

- Material handling facilities at the final destination.

- Climatic considerations.

- Air circulation.

- Packing for aesthetic appeal (do all products need to be visible Design and functionality of the handling equipment (e.g. robot gripper).

-

-

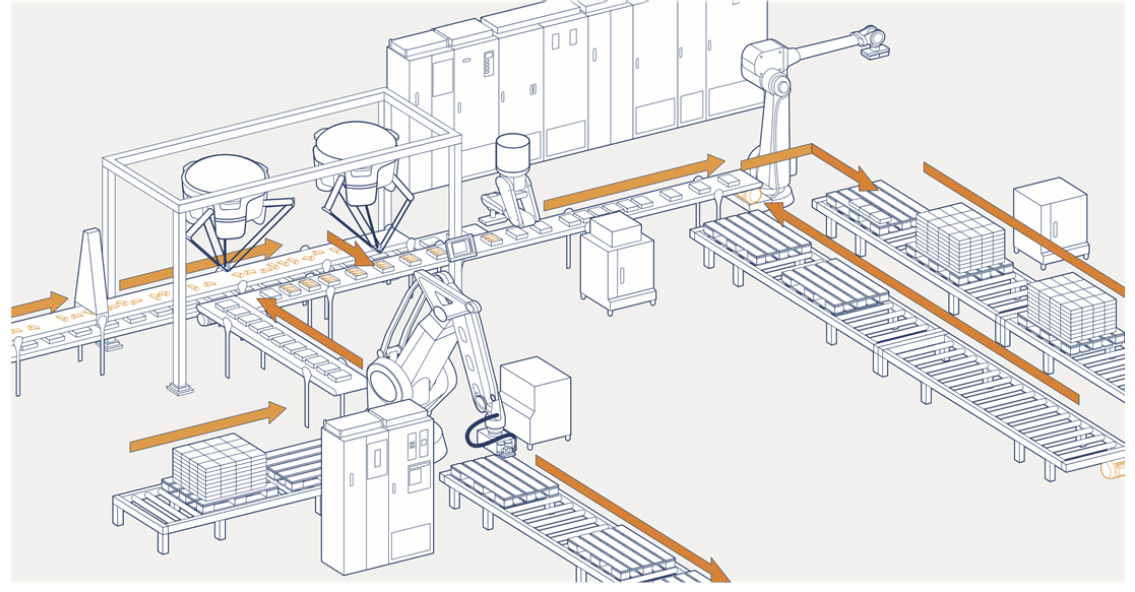

Picking, Packing and Palletizing Solutions

Robot-based automation ensures the kind of flexibility you need to meet ever shorter product life cycles, new packaging designs, product variants and batch manufacturing. Compared to dedicated hard automation, robot lines are shorter and allow better utilization of floor space.

Robot-based automation is an excellent alternative for manual operation. In addition to increased up-time and total throughput, fewer accidents and increasingly demanding workplace legislation are compelling reasons to make the shift to robotics.

Robots are usually associated with handling repetitive tasks in a process – either in high volume production roles or where flexible handling systems are needed for frequent changes. In the packaging industry, robots generally fall into three main arenas: pick and place applications, feed placement and palletizing. The ABB packing solution is given in the Fig.1.

Figure 1. Industrial packing solution

At ABB we build our robots to meet the most demanding work conditions – as well as the highest hygiene standards. All our robots are IP67 certified, ensuring tightly sealed joints and connectors.

The demands on quality validation and traceability are extremely high in pharmaceutical production. The absolute accuracy, repeatability and high up-time of ABB robots result in massive improvements over manual operation or dedicated production equipment. All our smaller robots suited to primary packing are verified for clean-room operation.

Picking

This is an area in which ABB services a multitude of products, applications and packaging line set-ups. Frozen food, bakery and confectionery, ice cream, meat and fish, pet food, medical products, shampoo and perfume bottles are a few examples. Industrial robot IRB 360 is the first 2nd generation delta robot – FlexPickerTM. Stainless steel versions are available for wash down duties such as in meat and dairy handling applications. Apart from even greater performance, the delta robot has a significantly increased payload of up to 3 kg – opening up further application possibilities, especially at the end of line. For full 6-axis flexibility, less demanding cycle times and payloads of up to 5 kg, we recommend the IRB 140.

Figure 2 ABB Delta robot for picking

Packing

In the packing stage of the packaging process, robot automation offers easy integration, increased flexibility and high reliability. Top loading of boxes, unloading and mixing, and feeding of products to end loaders or film wrappers is easily handled by ABB’s compact 4-axis IRB 260, a robot, designed and optimized for packing applications with a payload of up to 30 kg. With a comprehensive range of robots, controller equipment, vision technology and software, ABB can help you optimize all kinds of packing applications, including race track packing and tracking of moving conveyors.

Figure 3 ABB robot for packing

Palletizing

Placing boxes, trays, bags, bottles or other items on a pallet seems easy enough. But, when you’re dealing with the rigorous demands of multiple feeder lines, quick box-pattern changes and high up-time, nothing compares to robot-based automation. IRB 660 has the versatility, reach and handling capacity needed for most palletizing applications. And for even greater payload requirements, we recommend our standard 6-axis robots, the largest built to handle as much as 650 kg.

Fig 4 ABB 6 axes robot for palletizing

Special Tools for Packing

1. PalletPack 460 - Function package

PalletPack 460 is a package of pre-engineered products configured for end-of-line palletizing that greatly improves ease of use for integrators and lowers the hurdle to entry into automation. The function package, available for either highspeed bag palletizing or compact end-of-line case palletizing, consists of the IRB 460 palletizing robot, a Flex-Gripper, an ABB PLC, a Jokab Safety PLC, support software, user documentation and a FlexPendant that features a graphical HMI.

2. PickMaster

PickMaster is ABB’s standard software solution for integrating cameras, vision system and conveyors with picking, packing and palletizing robots. It is specifically designed for easy integration of ABB’s robots to a wide range of random material flow handling applications making it ideal for running combined high-speed picking and case packing systems.

PickMaster integrates up to 8 cameras and 8 robots and multiple conveyors for each robot using the industry benchmark – the Cognex vision system. The software can handle multiple in-feeders and multiple out-feeders in simultaneous production and houses quality control and inspection capabilities, as well as functions for advanced mixing and sorting of different products.

3. Conveyor tracking

ABB offers the market’s highest conveyor tracking accuracy, allowing picking and packing from conveyors – on the fly – without stopping the product flow. Thanks to synchronization of robots and conveyors, you can look forward to an increase in line speed as well as a healthy productivity boost.

4. FlexGripper palletizing grippers

ABB range of FlexGrippers includes a clamp, which comes in two sizes, for handling cases; a heavy-duty claw for high-speed bag palletizing; and a vacuum gripper that can handle up to five products at once.

5. RobotStudio Palletizing PowerPac

This program, which runs on a PC, allows users to configure, simulate and program ABB robots and grippers for palletizing solutions, with little or no robot programming experience required.

Robot applications

Mostly the industrial robots are quite universal, so one type is suitable for different applications. The primary is task description on the bases of which would be determined the basic type and parameters (technological possibilities) of an industrial robot. On the Fig..5 are presented different applications of industrial robots for different purposes.

Figure 5. Applications of industrial robots

Table 2 Technical parameters of industrial robots

| Robot | IRB 360 | IRB 120 | IRB 260 | IRB | 460 | IRB 660 |

| Load capacity (kg) | 1 - 3 | 3 | 6 | 30 | 110 | 180 / 250 |

|

|

0,8 /1,130/1,600 | 0,58 | 0,81 | 1,56 | 2,40 | 3,15 |

Figure .6 Grippers for packing and palletizing robots

Table 3 Technical parameters of grippers

| Gripper type | Clamp (Single zone) | Clamp (Double zone) | Claw | Vacuum |

| Gripper weight (kg) | 45 | 80 | 60 | 75 |

| Max weight / lift (kg) | 40 | 60 | 50 | 40 |

| Product type | Case

|

Case | Bag | Case, pallet |

Technical features of picking and packing robots

As in other robot application cases the technological capabilities or technical parameters of industrial robots depends of the industry task. In these applications (picking, packing, palletizing) the selection process starts from understanding the (group 1):

GR1

- Load capacity (kg)

- Reach (mm)

GR2

- Working space (coordinate system)

- Robot configuration

GR3

- Speed

- Repeatability (normally +/- 0.5 mm)

GR4

- Sensors used

- Gripper configuration

- Gripper types

References

[5.1] Paul F. Whelan, Bruce G. Batchelor. Automated packing systems: Review of industrial implementations.

[5.2] K.A. Dowsland and W.B. Dowsland (1992), "Packing problems", European Journal of Operational Research 56, 2-14. S. Dulio (1990), "Application of automation technology to leather cutting", Proceedings of the 23'rd International Symposium on Automotive Technology and Automation, 83-96. S. Dulio (1992).

[5.3] C. Malcolm and T. Smithers (1990), "Symbol grounding via a hybrid architecture in an autonomous assembly system", Robotics and Autonomous Systems 6(1,2), 123-144.

[5.4] E.l.Hall, R. Shell and G. Slutzky (1990), "Intelligent packing and material handling", Proc. SPIE Intelligent Robots and Computer Vision IX: Algorithms and Techniques 1381, 162-170.

[5.5] E.L. Hall, G.D. Slutzky and R.L. Shell (1989), "Intelligent robots for automated packaging and processing", Proc. ASME 1989 Pressure Vessels and Piping Conf., 141-146.

[5.6] A. Jain and M. Donath (1989), "Knowledge Representation System for Robot-Based Automated Assembly", Journal of Dynamic Systems, Measurement, and Control 111, 462-469

[5.7] R. Shoureshi, M. Momot, O.R. Mitchell and J. Feddema (1989), "Vision-based intelligent control for automated assembly", Journal of Intelligent and Robotic Systems 2, 153-170.

Example for specifications of bin picking robotics (E6)

Items Specifications

Measurement *1

Method Three-dimensional measurement using lasers

Distance 500 to 1 000 mm

Range 250 × 250 to 500 × 500 mm

Time Depending on the measurement range

Recognition

Method Recognition of three-dimensional shapes by comparison with three-dimensional data

Processing time Depending on the situation *2

Target object Parts, etc.*3 (min. 50 × 50 mm or so)

Basic configuration Control unit, robot*4, robot controller, hand*4, and range sensor

*1: These specifications are for the system shown in Fig. 1. The specifications vary depending on the type of sensor.

*2: The recognition time varies depending on the shape, quantity, and location of workpieces.

*3: Workpieces may not be measured or recognized depending on the surface material.

*4: The specifications of the robot and hand vary depending on the type of workpiece.

The examples of packing processes are presented on Figure below

Packing virtual solution Packing realization

Example for designing the robot cell for packing operations (E7)

Here we see one robot-packing use case for understanding what type of parameters form the suitability of use the packing robots in a company.

The first step is to understand the process:

1) Erecting the Cardboard

2) Loading Bottles

3) Packaging

4) Final Loading.

The second step is to declare the products and packages

Product for packing

Paper based package

Process description

1) Initially the robot Mi-200iC picks the case. The magazine is made up of cardboard.

2. The case magazine are then erected by the robot.

3. The same robot picks the bottles from the infeed conveyer. There are 12 bottles coming to the infeed conveyer

4. The bottles are then fully discharged to the erected cardboard.

5. The casing then goes for sealing through the conveyer where it is sealed with the plastic tape.

6. The case sealing machine then seals the case containing bottles and is further sent at the end of the conveyer belt.

7. The robot FUNAC Mi-10iA then carries the sealed case and places it at the package final placing location. The robot could carry 3 sealed cases here.

Packing workplace layout

Palletizing the boxes layout

Packing robot with technical description

The robot for palletizing was selected the robot Fanuc M-10iA/12 to place the cardboard that is filled with water from one place to another. Since it is having a payload of 12kg we could carry maximum 4 cardboard filled with water bottles. In our case we would be carrying 3 cardboards. This robot was selected because it has lower mass of 130kg as compared to other robots with same payload. It has maximum reach of 1420 mm which is a big advantage in our case as it covers larger range so I have chosen this robot. [5]

Robot for palletizing and its technical parameters

It was understood that few parameters like workload, speed, efficiency, etc. should be chosen when selecting a robot. An idea regarding the structure of working place of Fanuc robot was understood for Mi-200iC and Mi-10iA. Both of the robots are of different type i.e. Mi-200iC for handling smaller load and has lower mass while the other having larger mass and handling higher payload. Apart from these, the work cell design and layout for any production system which involves robot was also understood. It was necessary to taken into consideration that the working space of robot has to be always covered by some protection barrier in order to create a safe working environment.

References

[1] P.F. Whelan and B.G. Batchelor (1991), "Automated packing of arbitrary shapes", in Proc. SPIE Machine Vision Architectures, Integration, and Applications 1615, 77-86.

[2] P.F. Whelan and B.G. Batchelor (1992), "Development of a vision system for the flexible packing of random shapes", in Proc. SPIE Machine Vision Applications, Architectures, and Systems Integration 1823, 223-232.

[3] SVG, "Robotic Manufacturing Systems," SVG Publications, Delhi, 2012.

[4] "Robotic Case Effector and loader," 2016. [Online]. Available: http://www.esstechnologies.com/Products/CEL5-Case-Erect-Load.shtml.

[5] G. Martin, "Robotic Cell Layout Production," Bastian Robotics, 2014. [Online]. [Accessed 16 01 2018].

[6] FUNAC, "FUNAC Mi-200iC," FUNAC, 2012. [Online]. Available: https://www.robots.com/fanuc/lr-mate-200ic-5lc. [Accessed 13 1 2018]

[7] FUNAC, "M-10iA/12," FUNAC, 2014. [Online]. Available: http://www.fanuc.eu/ch/en/robots/robot-filter-page/m- 10-series/m-10ia-12. [Accessed 7 1 2018].

[8] R. systems, "Robotic Palletizers," RHM systems, [Online]. Available: http://www.rmhsystems.com/productcategory/robotic-palletizers/. [Accessed 12 1 2018].

[9] CE, "Semi-Automatic Cartoon Sealer," CE Cleveland Equipment and Machinery, [Online]. Available: http://clevelandequipment.com/ce-551tb-uniform-semi-automatic-folding-carton-sealer.html. [Accessed 15 1 2018].